General PWB

Product proposal

Thin rigid PWB

Concept

●Polyimide material has been a common choice for use of bended printed wiring board, but aren't they excessive implementation?

●Polyimide material has been a common choice for use of bended printed wiring board, but aren't they excessive implementation?

●In case where the angle of bending is not an acute angle, or where a bending or repeated bending is not involved, the bending and fixing purposes can be fulfilled without using expensive polyimide.

●Partial use of a reinforcing board to a PWB made with polyimide (conventionally called a flexible PWB) would add the procedure of reinforcement and, therefore, would make the product more expensive. Usng thin material with the equivalent thickness instead would eliminate the procedure.

●Resist formulation by painting resist ink and using photographic method, instead of using polyimide cover lay film, can achieve high precision. Mass production can also reduce the price (our suvery data).

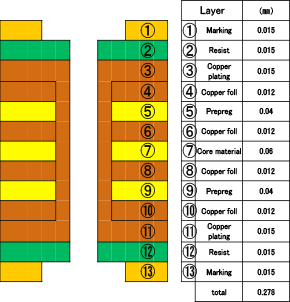

4-layer layer configuration example of

a thin rigid board

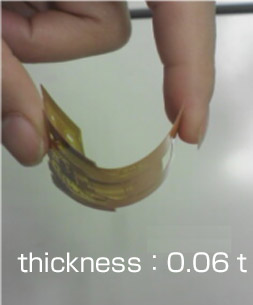

Bending test of the 2-layer thin rigid board

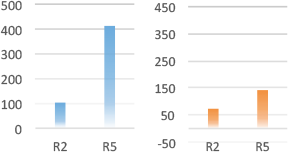

① TEST CONDITION

thickness:0.12mm (FR-4/0.04mm/18μm)

Test speed:100/175cpm Bending angle:135°

Bending R:2mm/5mm Weigt:500g

② TEST MACHINE

③ TEST RESULTS